Pavement Evaluation & Design

Our pavement design and evaluation services meet the needs for all types of traffic requirements. Our engineers have a comprehensive understanding of pavement design and evaluation standards from government agencies and industries including the Federal Aviation Administration (FAA), American Association of State Highway and Transportation Officials (AASHTO), and the military. We stay on top of changes and emerging technology in pavement design methods and materials. Our designs incorporate energy and material conservation, as well as environmental consequences as part of sustainable design principles. Our proficiency in widely-used design software such as FAARFIELD, DARWin-ME, and PCASE makes it possible to deliver designs on time, on budget, and based on a solid engineering foundation.

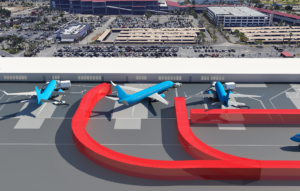

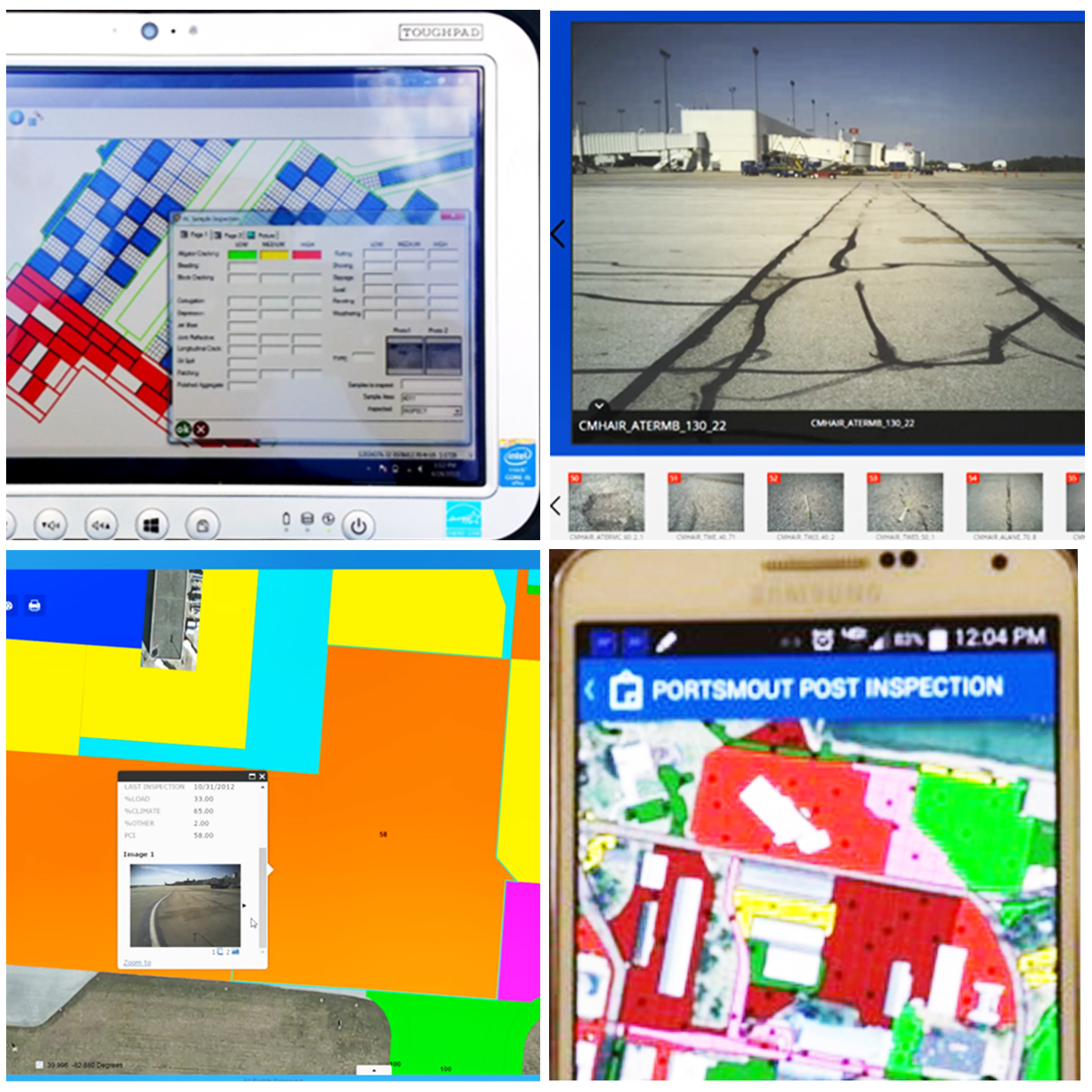

Pavement Maintenance & Management

Pavements are a critical element of the infrastructure and provided an important role in our economy. A well-maintained pavement system is a must to provide satisfactory service to the users. Our goal is to help our clients build and maintain a robust pavement management system. Using state-of-the-art industry technology, equipment, and software, our professionally trained team can provide a clear picture of the current functional and structural pavement condition and beyond. A comprehensive maintenance program can be established with time, measures, and budgets based on sound engineering analysis. We have successfully delivered over more than 200 pavement management systems both civilian and military airports, highways, and seaports. A pavement management system provides direction on the maintenance and repairs that provide the greatest value for the funds allocated.

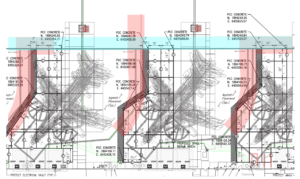

Civil Engineering Design

RDM provides a full range of civil design services for airports, roadways, parking facilities and military installations. RDM has designed runways, taxiways, ramps and service roads at some of the largest airports in the United States. RDM takes into account whole project and ensures everything meets the intent of the FAA Advisory Circulars and standards.

Investigation & Research

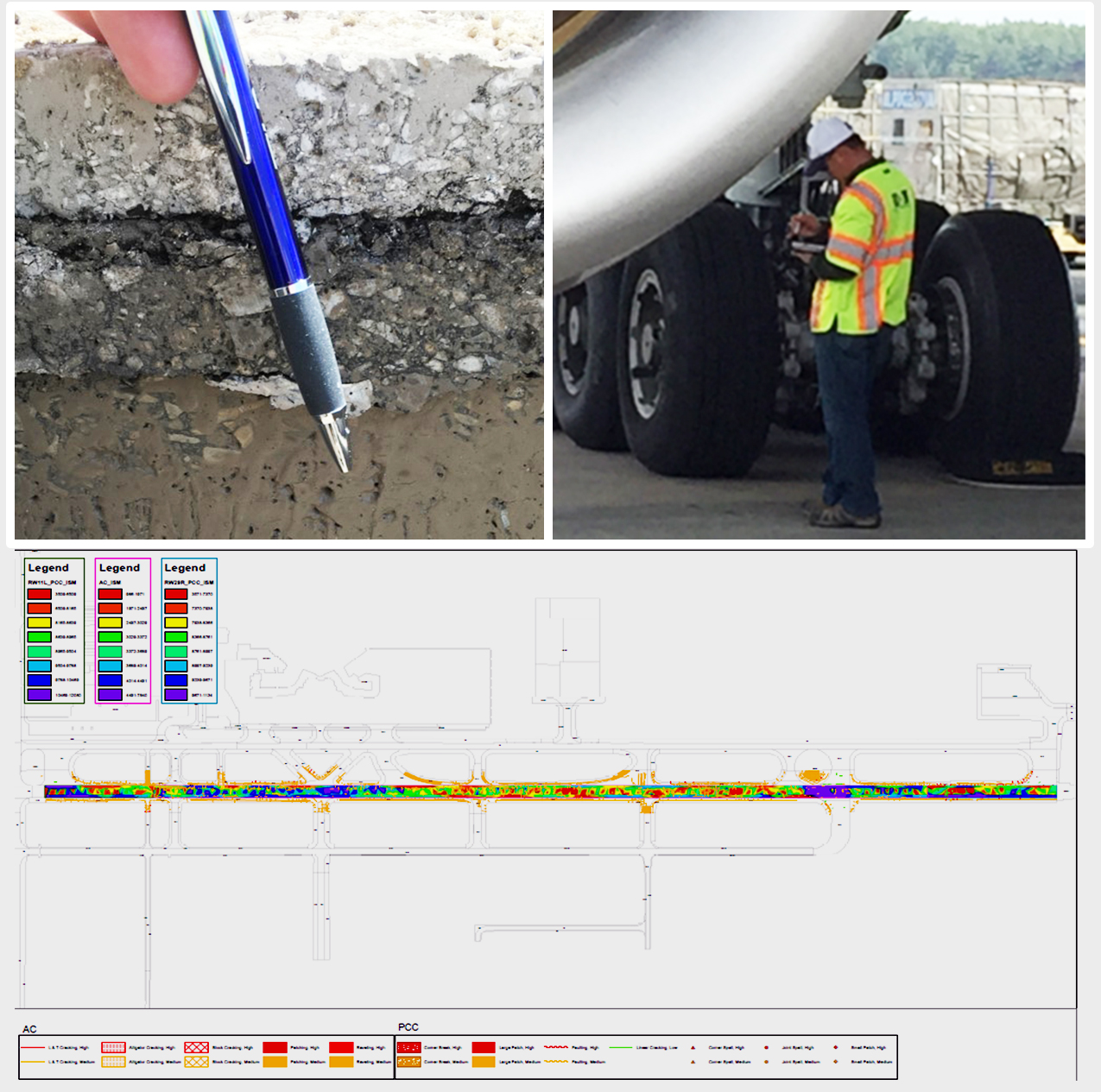

Our experience and “hands-on” approach enables us to focus our pavement research efforts on practical

application and implement-able results. This experience provides insight to issues that arise during the design or construction of various types of pavements. To date, we have conducted pavement related research on materials, structural pavement design, nondestructive testing, construction methods, roughness, and new materials for the FAA, state governments and commercial clients. These include airport pavement research projects on Hot Mix Asphalt (P-401), Portland Cement Concrete (P-501), airport pavement recycling, asphalt binder selection, mechanistic design methods, etc. Our work has been used to update or develop FAA standards and Advisory Circulars regarding airport pavement materials, design procedures, and recycling methods.

Investigations have included a review of materials suppliers in the vicinity of pavement projects to assure that materials meet all specification requirements and will not result in problem pavement such as ASR. This preventative approach decreases the chances of replacing a pavement shortly after it was installed.

Aviation Planning

RDM now provides professional services to meet all of your aviation planning needs. Our staff has performed work internationally and in the United States on civilian and military facilities. We provide a holistic approach to planning that incorporates all elements of your airfield including airspace and alternatives to provide a wide range of opportunities when it comes to your airport.

Geographic Information System

One of the most complex aspects of managing pavements is having a strong understanding of the pavement network and the geographic location and size of all pavements. Integrating GIS with pavement management combines all of the data with a spatial database. Linking the GIS with the data in PAVER allows the data to be linked and incorporated into a larger GIS database. Our NDT equipment is capable of recording GPS locations that can be linked with the pavement survey data and incorporated in any GIS database. Our goal is to help you integrate pavement related data into you’re A-GIS system to create a “one stop data shop”.

Construction Management & Service Support

RDM has been providing full-service Construction Administration Services for the past five years. Our CM team brings extensive experience in both design and construction of pavements, so they literally know the construction process from the ground up! RDM works with engineers and contractors to ensure all design criteria are met and quality is never sacrificed. RDM’s construction support services include constructability reviews, value engineering, CSPP and 7460 preparation, pavement material submittal review, construction scheduling, construction observation/documentation, trouble shooting, and dispute resolution. With a strong understanding of design goals and construction practices, we assist design professionals and owners with development of construction details and specifications for inclusion in contract bid documents that set realistic criteria while ensuring the highest quality.

RDM tailors material specifications to the specific needs of the project based on location, sub-grade characteristics and anticipated traffic loads. This results in a pavement section prepared for the location and its conditions. One size does not fit all at RDM.

RDM provides video and photo documentation of large worksites with our small Unmanned Aerial System (sUAS or Drone) to cover large areas quickly while keeping the “big picture” in sight. RDM has obtained waivers from the FAA allowing sUAS operations at night to document night construction operations and methods such as off-peak paving.